Automatic Konjac Noodle Making Machine | Shirataki Noodle Machine

Features

Features

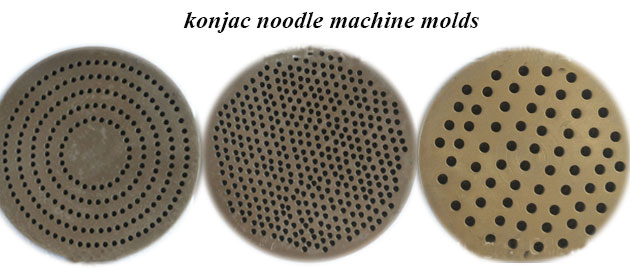

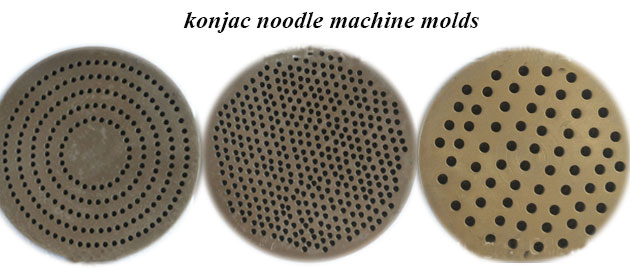

The India konjac noodle machine can make different types of finished products by changing molds, such as round, flat, wide, thin noodles.

Konjac Noodle Machine Features:

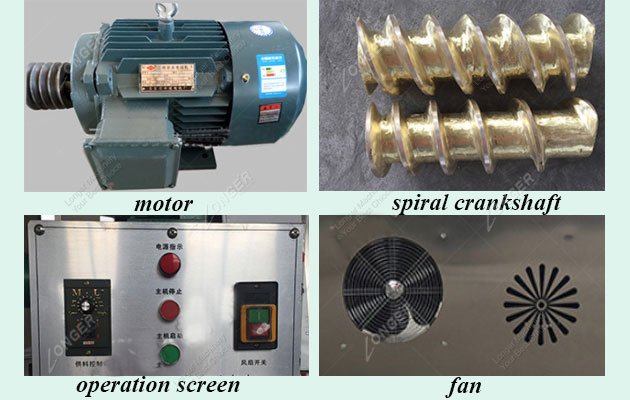

1. Advanced self-cooking process, the finished taste is smooth and not easy to break.

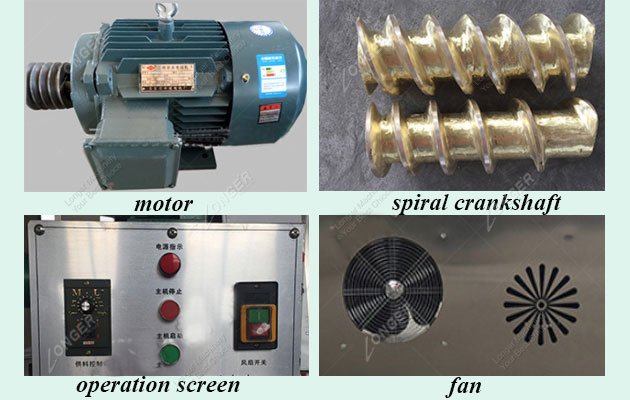

2. The automatic cutting function is controlled by the variable frequency speed control motor.

3. Independent operation of the control panel, the function is clear at a glance, the operation is simple and convenient.

4. Double fan motor heat sink, user-friendly design, the finished product does not stick.

5. National standard pure copper motor, one year warranty, lifetime maintenance.

6. The spiral crankshaft is made of pure copper and is integrally formed. It has high wear resistance and fast heat conduction. The whole machine has no wearing parts and is durable.

Shirataki Noodle Machine Working Principle:

On the basis of the traditional spiral extrusion machine, the electrothermal konjac noodle machine is equipped with the intelligent temperature control device for direct heat of water bath. Various starches are cooked at high temperature by circulating hot water, it ensures the stability of starch gelatinization, and changes the disadvantages of traditional models, such as friction heat generation, unstable temperature and uneven product curing.

Matters Needing Attention:

1. After the production is completed, the residual materials in the shirataki noodle machine should be washed with clean water in time to remove the remaining materials in the machine head.

2. The cooking water in the cylinder should be checked and added frequently during the production process.

3. In case of "stuck machine", the power shall be cut off immediately and the shirataki noodle machine head shall be removed, with the appropriate size of the iron bar or fixed wrench, from the feed mouth, into the feed mouth, the "guide bar" pry out, clean up, in accordance with the original position, then continue to produce.

Konjac Noodle Machine Features:

1. Advanced self-cooking process, the finished taste is smooth and not easy to break.

2. The automatic cutting function is controlled by the variable frequency speed control motor.

3. Independent operation of the control panel, the function is clear at a glance, the operation is simple and convenient.

4. Double fan motor heat sink, user-friendly design, the finished product does not stick.

5. National standard pure copper motor, one year warranty, lifetime maintenance.

6. The spiral crankshaft is made of pure copper and is integrally formed. It has high wear resistance and fast heat conduction. The whole machine has no wearing parts and is durable.

Shirataki Noodle Machine Working Principle:

On the basis of the traditional spiral extrusion machine, the electrothermal konjac noodle machine is equipped with the intelligent temperature control device for direct heat of water bath. Various starches are cooked at high temperature by circulating hot water, it ensures the stability of starch gelatinization, and changes the disadvantages of traditional models, such as friction heat generation, unstable temperature and uneven product curing.

Matters Needing Attention:

1. After the production is completed, the residual materials in the shirataki noodle machine should be washed with clean water in time to remove the remaining materials in the machine head.

2. The cooking water in the cylinder should be checked and added frequently during the production process.

3. In case of "stuck machine", the power shall be cut off immediately and the shirataki noodle machine head shall be removed, with the appropriate size of the iron bar or fixed wrench, from the feed mouth, into the feed mouth, the "guide bar" pry out, clean up, in accordance with the original position, then continue to produce.

Technical Data

Technical Data

| Model | LG-30 | LG-60 | LG-100 | LG-250 |

| Voltage | 220V/380V | 220V/380V | 380V | 380V |

| Power | 3KW | 3KW | 7.5KW | 15KW |

| Capacity | 30kg/h | 60kg/h | 100kg/h | 250kg/h |

| Dimension | 950*400*1200mm | 980*430*1200mm | 1100*450*1300mm | 1230*1100*1600mm |

Related Products

Related Products